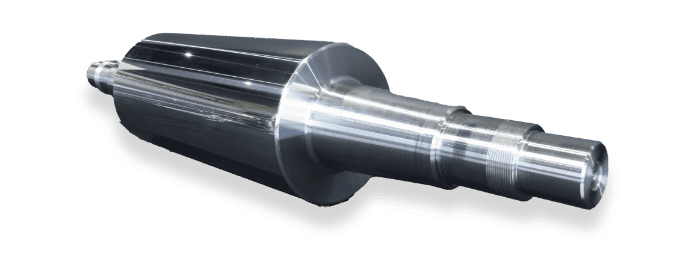

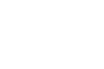

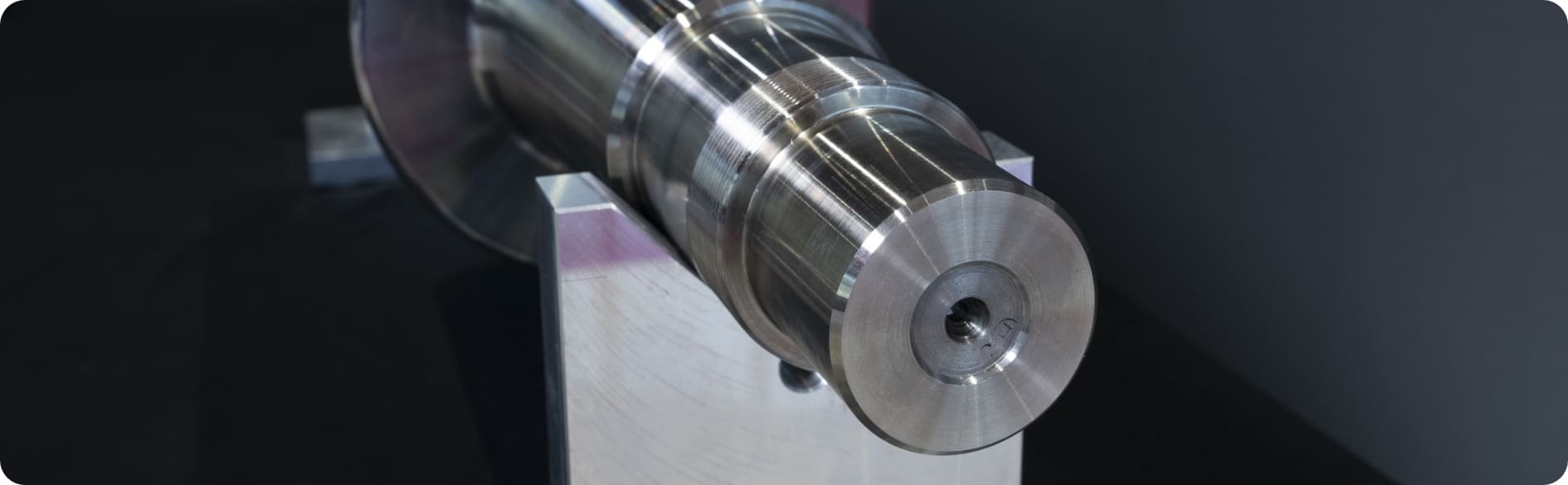

・Alternative to hard chrome plating

Hard chrome plating is indispensable for industrial products, but due to recent environmental regulations, the number of plating companies has been decreasing and plating has become a bottleneck.

In response to this situation, we have developed an alternative product to secure a higher production volume than before. In addition, now that surface treatment can be done in-house, the entire process can be done in-house, allowing for quicker delivery.

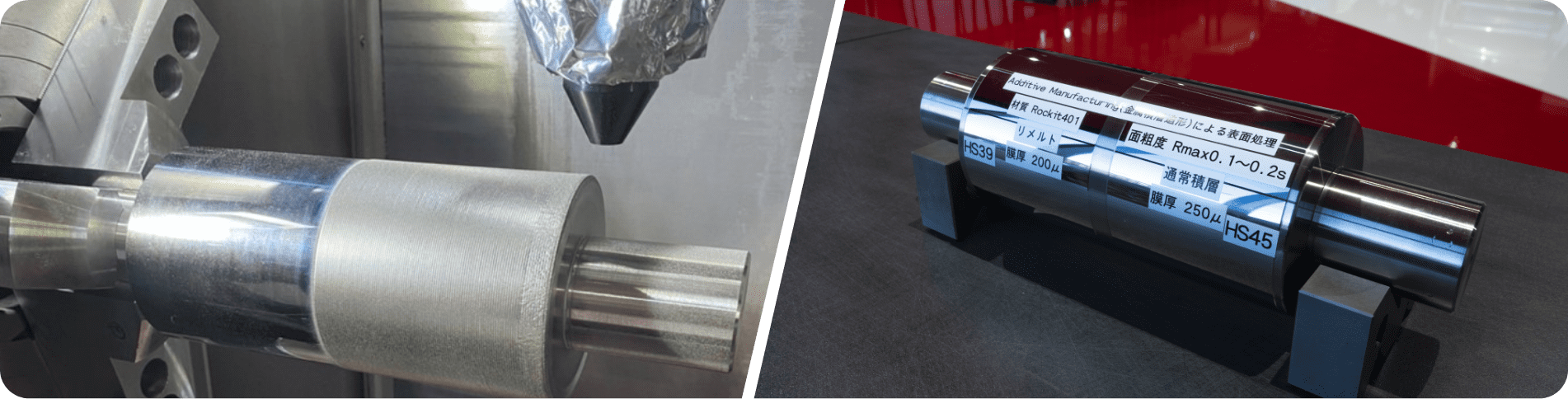

・Existing products can be reproduced

Unlike welding, no thermal distortion is caused by the overlay, and repairs can be made exclusively to the failed part.

Until now, it has not been possible to repair worn rolls with extremely small outer diameters. However, with lamination, it is possible to repair rolls in any condition because the surface can be reconditioned to an exact millimeter thickness.

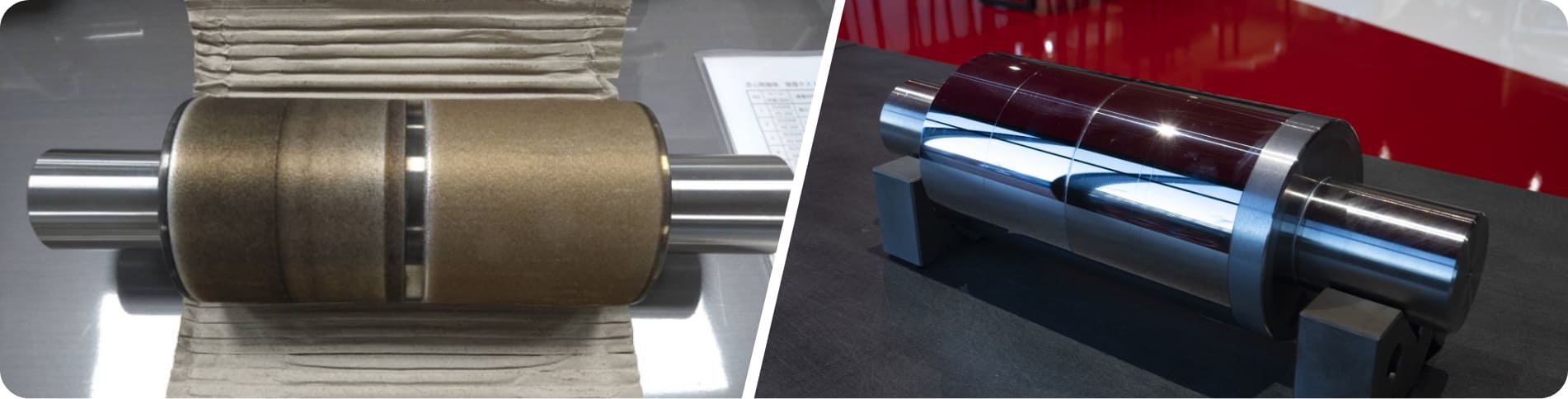

・Converting inexpensive materials into highly functional materials

When high-performance materials such as SUS316L or Hastelloy are required, material costs are very high. By using Hikoyama Seiki's surface treatment technology, it is possible to manufacture inexpensive rolls that boast high-end functionality. This is achieved by manufacturing a core made of inexpensive materials and using high-performance metal only for the surface that comes in contact with the chemicals. This leads to a significant reduction in material costs.

contact

For inquiries, please contact us here.