Our Features

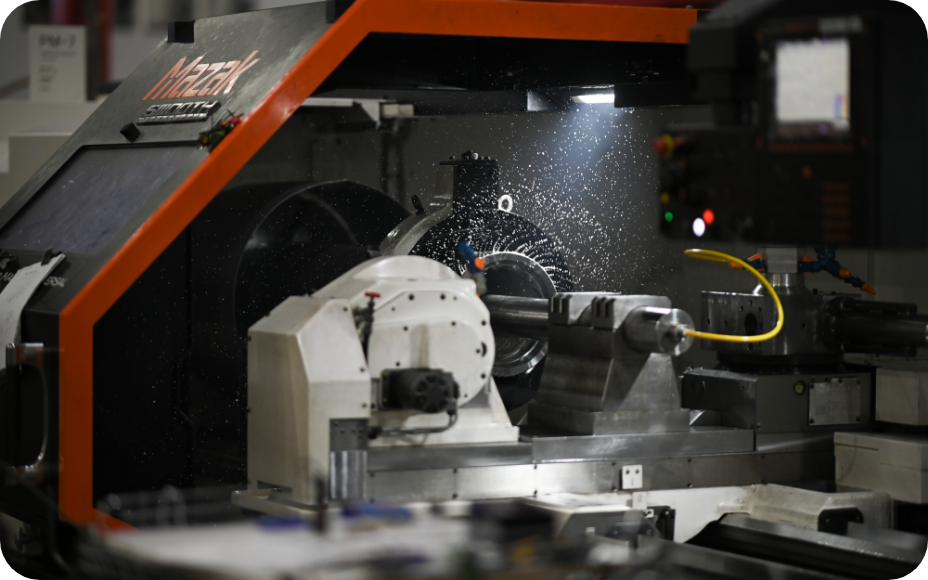

01Abundant Processing

Facilities

Hikoyama Seiki's strength lies in its abundant processing facilities. From cutting to canning and polishing, all processes are handled in-house in an integrated manner. We have created an optimal environment for pursuing high quality and have built a system to meet every need. This is the source of our technological strength allowing us to stay one step ahead.

02Integrated Production from

Design to Manufacturing

Our aim since our establishment about half a century ago has always been to continue to meet all kinds of requests with our design and manufacturing know-how, backed up by our experience in meeting roll-related requests as a specialized manufacturer. We can also measure and manufacture rolls and equipment. We welcome your consultation on the design of products we can develop.

-

Design Process

Having skilled designers allows us to perform strength calculations and incorporate special features in development projects and other projects undertaken from the design stage.

We can also provide drawings, even if the client only has an abstract idea of what the project will look like or if we are consulted at the conceptual stage. -

Manufacturing Process

We have facilities that allow us to consistently perform all processes in house, and we conduct tight quality control. We assure high-quality products and rapid response to any issues.

-

Quality Control

Inspection of balance, etc. is performed mid-stage.

This is to avoid cases in which defects in dimensions and balance are found in a subsequent process, making it difficult to correct.

In addition, we submit inspection sheets to all customers, firstly to ensure that the required quality is met, but also to ensure traceability in case of any subsequent issues.

Measurements are taken by reproducing not only the quality of the rolls themselves, but also the conditions under which they are installed in the equipment, so that the process from actual installation to operation can be carried out smoothly. -

Contract Processing

In addition to roll manufacturing, we also accept requests for the balancing of rolls and machining of parts.

Please feel free to contact us for a consultation regarding high-precision polishing, microfabrication, and cutting.

03Challenges in New Fields

We are embracing challenging new fields based on our state-of-the-art facilities and long-standing know-how, such as creating mold rolls for optical films, including brightness-enhancing films for LCD TVs and smartphones.

If you wonder "Is it possible to do this kind of processing?", we would be happy to hear from you.

04Knowledge of Materials

Just as in the production of food, it is important to be particular about the materials used in manufacturing rolls.

We select the most suitable materials based on the customer's requirements and specifications, and we also perform heat treatment at the roughing stage to maximize material properties to produce high-quality, high-precision rolls.

contact

For inquiries, please contact us here.