・In-depth know-how of microfabrication and various types of pattern processing techniques

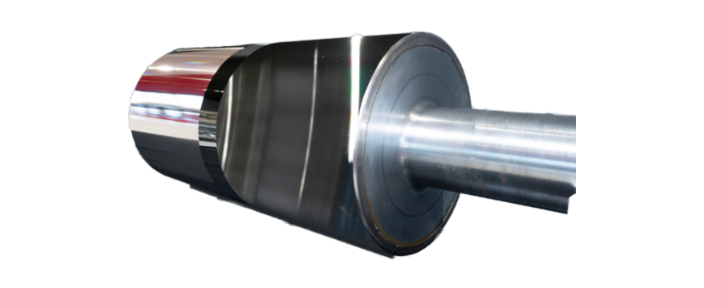

We can perform microfabrication of rolls that serve as molds for optical films (prism sheets, lenticular, etc.).

We perform various methods of processing, such as single/multi-strip cutting, ring cutting, cross cutting, and horizontal drawing. We also conduct micro-processing for components other than optical systems.

We also offer microfabrication services for existing rolls owned by our customers.

・Microfabrication on large rolls

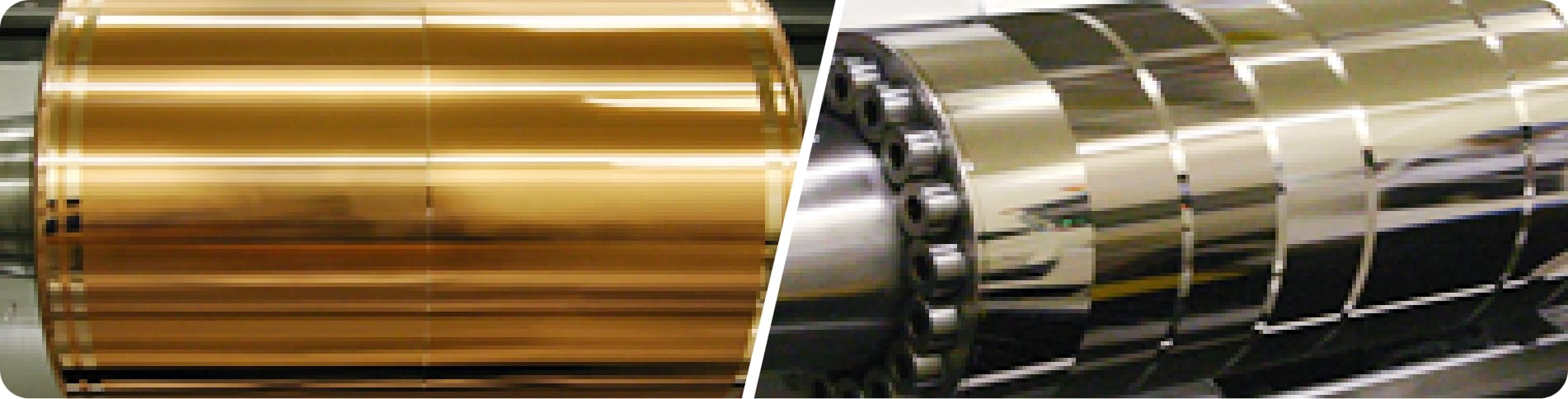

For Cu plating, microfabrication of rolls up to MAX 600mm x 2000mm (face length) is possible.

For Ni-P plating, we can provide microfabrication of rolls up to MAX 450mm x 2000mm (face length).

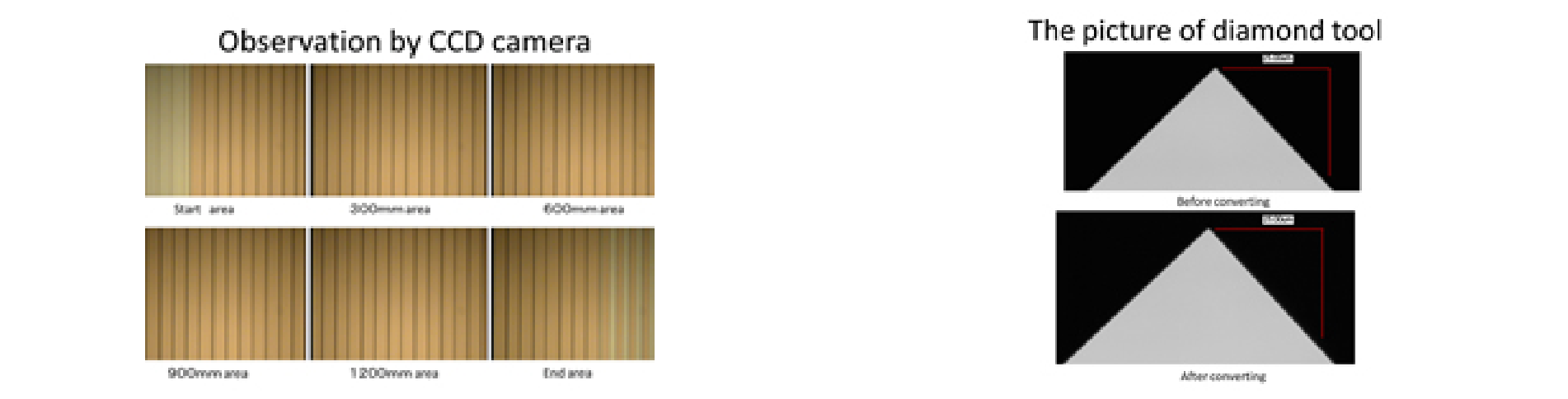

・Laser microscope, CCD camera for magnified observation

A laser microscope is used to check for chipping or wear of the processing tool and to check the replica after processing.

We also use a CCD camera to examine for any abnormalities during processing.

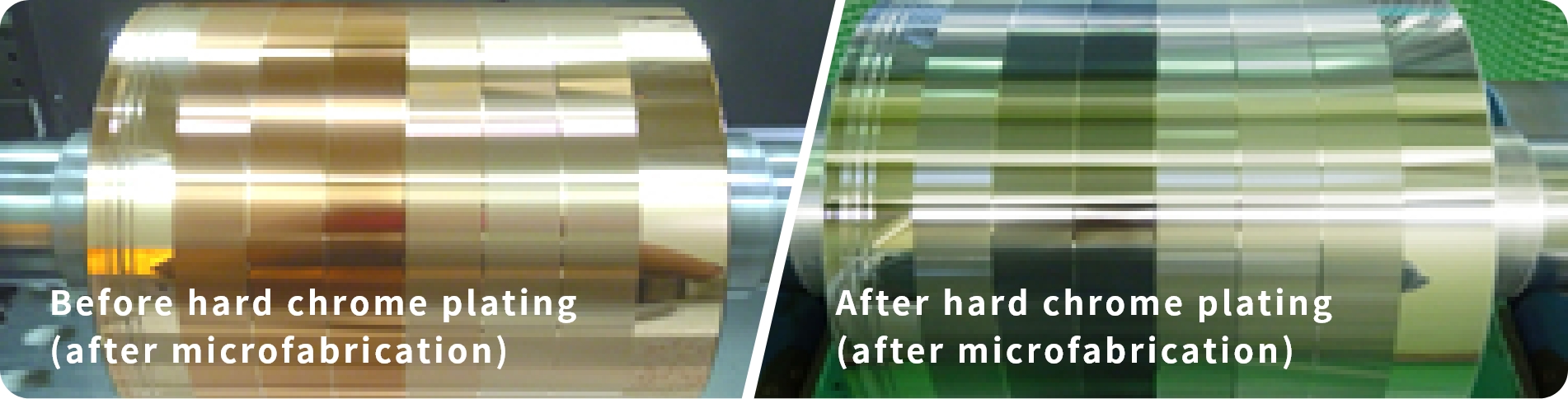

・Microfabrication + hard surface treatment

After microfabrication of Cu or Ni-P plating, the surface can be treated with hard chrome plating.

Hard chrome plating prevents surface scratches.

contact

For inquiries, please contact us here.